The only uniform fabric made from a circular economy

Ecowork is the first sustainable fabric for professional uniforms developed by Ideal Work, the result of a circular-economy production chain.

What is Ecowork?

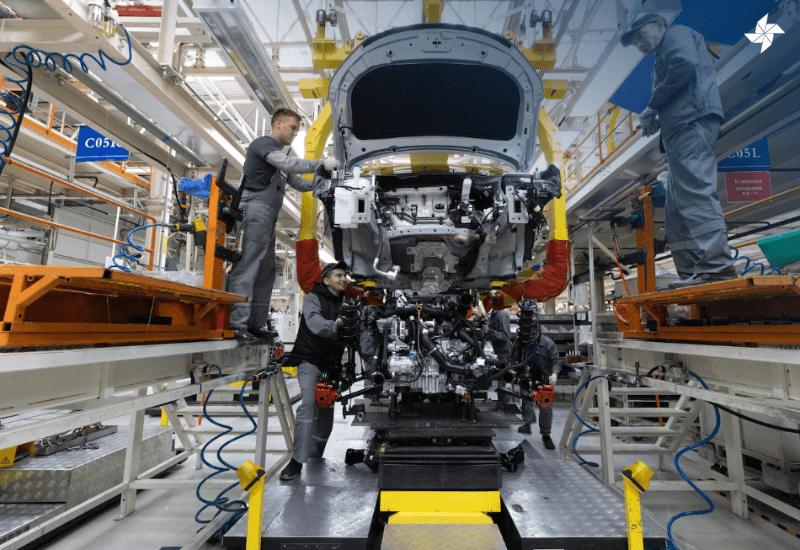

Ideal Work, the largest manufacturer of professional uniforms in Brazil, is innovating once again. After being the first to operate in the flame-resistant market and launching an online uniform store, it became a global pioneer by launching Ecowork—a uniform fabric resulting from a fully sustainable production chain developed by the company.

Ecowork is the only fabric for professional uniforms made through a circular economy process, where waste returns to become the same product it originally was. In manufacturing, used uniforms collected from clients and production residues are fiberized and blended with other fibers such as cotton and polyester—adding durability and resistance to the yarn—then transformed into fabric and uniforms, closing the loop.

What is Ecowork made of?

Ecowork is the result of two years of exhaustive research to reach the ideal composition: a fiberized fabric blended with cotton and polyester, which provide thermal comfort and durability to the final fabric—mixed twill, the most widely used for professional activities across companies.

Ecowork has been tested in accredited laboratories, according to all national and international standards, and can be produced in multiple colors to meet your company’s needs.

How does the circular economy work?

Ecowork is a natural step for Ideal Work—an organization with environmental conservation in its DNA.

The fabric was born from a conscious disposal program maintained by the company for years. Through it, Ideal Work—together with its clients—ensures the correct destination for used uniform waste.

Ecowork is also an important asset at a time when adopting ESG practices, besides benefiting the planet, also influences companies’ market value.

Quality and origin assured

Ideal Work was extremely demanding and strategic in selecting the entire production chain, ensuring suppliers with compatible values and sustainable processes.

The company also hired an international certification body, DNV, to ensure credibility and traceability across the entire chain—proving the cycle and reuse of residues.

Ecowork’s sustainable cycle

Fiberizing

Used uniforms and textile residues are washed, de-branded, and fiberized until they become a fluff-like fiber.

Spinning

The fiber is used to produce yarn.

Weaving

Ecowork is produced from the fiberized yarn combined with BCI yarn (100% cotton).

Manufacturing

Ecowork is used to manufacture the new uniforms.

Clients who trust us

Uniforms made with Ecowork always include recycled and biodegradable trims and packaging

Recognition that reflects our commitment to excellence

Request a personalized quote

Our team is ready to develop the ideal uniform for your company using Ecowork. Contact us and schedule a personalized quote.